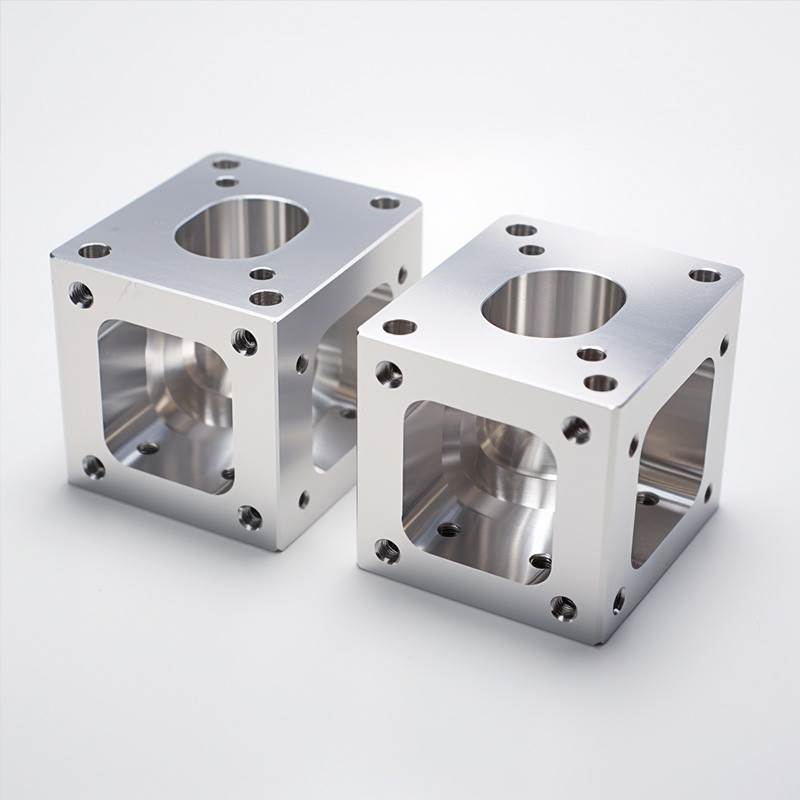

CNC Processing Machining Parts Aluminum Parts CNC Machining CNC

Milling Auto Part

While traditional machining involves a skilled machinist manually

operating a machine to remove

or shape metal based on specifications from designers and

engineers, CNC machining performs

the same metal cutting, drilling, milling, boring, grinding, and other

metal forming and removal

functions with a crucial distinction — it employs computer

numerical control rather than manual

operation.

Traditional machining relies on tools such as turn wheels, dials,

switches, chucks, vices, and

cutting tools made of materials like hardened steel, carbide, and

industrial diamond.

Measurements are taken to ensure accuracy. In contrast, CNC

machining is automated and

code-driven, developed by programmers. It delivers consistent

precision from the initial cut to

subsequent repetitions, making it suitable for digital

manufacturing and low-volume production.

CNC machining's advantage lies in its flexibility for revisions and

alterations, accommodating

modifications and different materials with ease. While traditional

machining retains its place,

CNC machining has largely taken over in manufacturing, fabrication,

and industrial production

due to its superior precision and automation.

Product Details

CNC machining materials are generally grouped into three primary

categories:

plastics, soft metals, and hard metals. This classification

includes materials such as aluminum,

bronze, copper, ceramics, plywood, steel, stone, wood, zinc, and

various others.

Preference is often given to materials that are considered easy to

work with and possess

advantageous properties compared to alternative options.

| Common Materials for CNC Machining |

| Material | Properties |

| Aluminum | 2024: Good fatigue resistance and strength; excellent toughness at

moderate to high strength levels; improved fracture toughness |

| 6061: Excellent machinability, low cost, and versatility |

| 7075: High strength, hardness, low weight, and heat tolerance |

| Brass | Versatile and highly attractive copper/zinc alloy with warm yellow

color accommodates severe forming/drawing |

| Copper | High ductility and high electrical and thermal conductivity;

develops attractive blue-green surface patina over time |

| Stainless Steel | Excellent machinability and outstanding uniformity; good

workability and weldability, high ductility and formability |

| Steel Alloy | Mix of chromium, molybdenum, and manganese yields toughness, good

torsional and fatigue strength |

| Steel Mild Low Carbon | High machinability and weldability, high stiffness; good mechanical

properties, machinability, and weldability at low cost |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive,

and medical industries |

| ABS | Excellent impact resistance, good mechanical properties,

susceptible to solvents |

| Nylon | Excellent mechanical properties, high toughness, poor moisture

resistance |

| POM | High stiffness, excellent thermal & electrical properties,

relatively brittle |

| CNC Milling Tolerances |

| Limits for nominal size | Plastics | Metals |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.10mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.20mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.30mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.50mm |

| Over 2000mm to 4000mm | ±2.0mm | |

*Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing. |

CNC Machining Applications

The utilization of CNC machining spans a multitude of industries,

with a significant presence in

aerospace, automotive, consumer electronics, robotics, and

agriculture, particularly in the

production of metal components.

Beyond these, CNC machining is integral to the manufacturing

processes of medical devices,

household goods, and various consumer applications. Its prevalence

extends into sectors such

as energy, oil and gas, making CNC machining one of the most

pervasive and essential

manufacturing techniques globally.

Company Profile

FAQ's

1. How much import duty will I need to pay for my goods?

The amount of import duty for your goods is not standardized and

varies based on several factors.

In Australia, the introduction of new CHAFTA regulations allows for

a progressive implementation

of duty-free imports. Import duties differ widely and are

determined by the type of goods being

imported. Globally, most countries adhere to international

Harmonized System (HS) codes,

which categorize nearly all commercial trade goods.

2. What if I am not completely satisfied with the parts I receive?

We assure the quality of our materials and workmanship based on the

terms specified in the initial

order and the information you provide. Disputes arising from

subjective assessments will be

handled by our management, who will act in good faith to secure

your complete satisfaction.

Our sustained success hinges on earning your confidence in our

ability to consistently meet

and exceed reasonable expectations.

3. Do you offer Quick-Turn CNC Machining?

Indeed! Our Quick-Turn CNC Machining services provide fast lead

times for parts, with many available

within 3-4 days. We also offer an expedite option, and our team is

dedicated to working closely with

you to meet your most pressing deadlines.