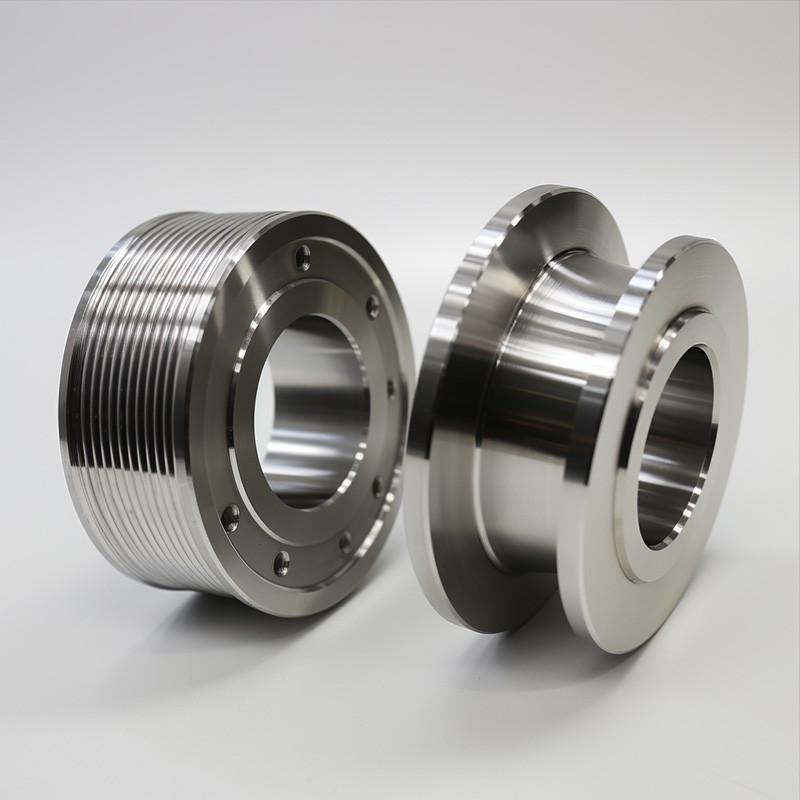

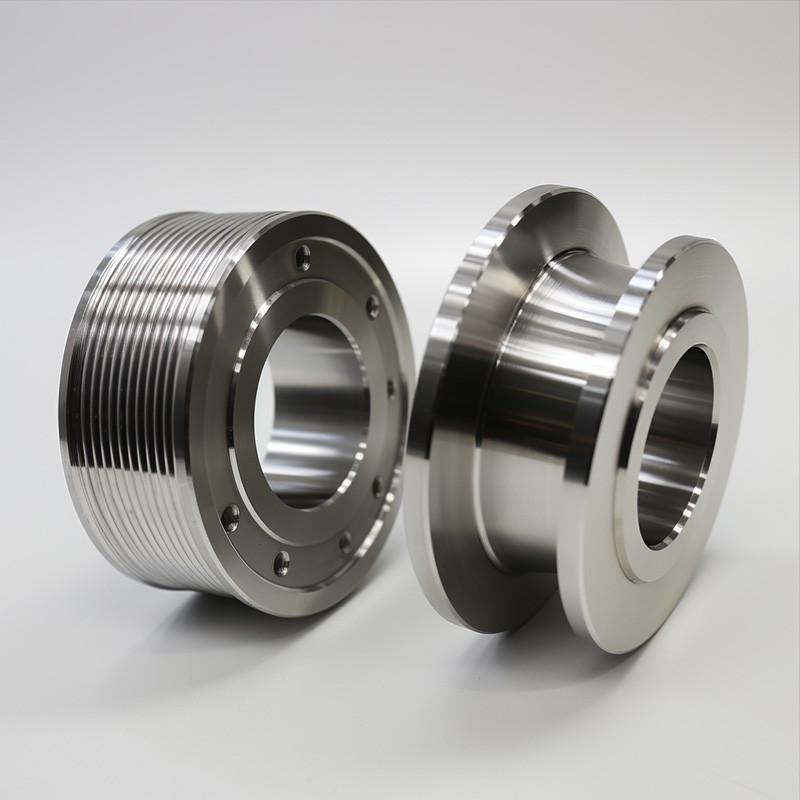

CNC Machining Turning Small Spare Parts Stainless Steel Material

CNC Machining

Mini CNC Parts

While traditional machining involves a skilled machinist manually

operating a machine to remove or

shape metal based on specifications from designers and engineers,

CNC machining performs the

same metal cutting, drilling, milling, boring, grinding, and other

metal forming and removal

functions with a crucial distinction — it employs computer

numerical control rather than manual

operation.

Traditional machining relies on tools such as turn wheels, dials,

switches, chucks, vices,

and cutting tools made of materials like hardened steel, carbide, and

industrial diamond.

Measurements are taken to ensure accuracy. In contrast, CNC

machining is automated and

code-driven, developed by programmers. It delivers consistent

precision from the initial cut to

subsequent repetitions, making it suitable for digital

manufacturing and low-volume production.

CNC machining's advantage lies in its flexibility for revisions and

alterations, accommodating

modifications and different materials with ease. While traditional

machining retains its place,

CNC machining has largely taken over in manufacturing, fabrication,

and industrial production

due to its superior precision and automation.

Product Details

CNC machining encompasses a wide variety of materials, each

requiring specific machining

parameters for optimal performance. The most common materials

include:

1. Metal:

Metal is the predominant material in CNC machining, with the

ability to cut various types, from

brass to nickel superalloys like Inconel. Applications range from

injection molds to shafts and gears.

2. Plastic:

While injection molding is common for plastic parts, CNC machining

is used for specific components

like ABS, nylon, and polycarbonate. Applications include valve

bodies, bushings, and injection

molding prototypes.

3. Wood:

CNC routers are frequently employed for wood cutting, especially

for decorative purposes like

furniture, window frames, and ornamental panels.

4. Foam:

Polyurethane foam, both closed and open-cell, finds application in

CNC machining for creating

secure packaging, such as foam used in toolboxes for tool

transportation.

5. Composites:

CNC machines are essential for processing abrasive composite

materials like aramid, fiberglass,

and carbon fiber, commonly used in aerospace and marine components.

| Common Materials for CNC Machining |

| Material | Properties |

| Aluminum | 2024: Good fatigue resistance and strength; excellent toughness at

moderate to high strength levels; improved fracture toughness |

| 6061: Excellent machinability, low cost, and versatility |

| 7075: High strength, hardness, low weight, and heat tolerance |

| Brass | Versatile and highly attractive copper/zinc alloy with warm yellow

color accommodates severe forming/drawing |

| Copper | High ductility and high electrical and thermal conductivity;

develops attractive blue-green surface patina over time |

| Stainless Steel | Excellent machinability and outstanding uniformity; good

workability and weldability, high ductility and formability |

| Steel Alloy | Mix of chromium, molybdenum, and manganese yields toughness, good

torsional and fatigue strength |

| Steel Mild Low Carbon | High machinability and weldability, high stiffness; good mechanical

properties, machinability, and weldability at low cost |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive,

and medical industries |

| ABS | Excellent impact resistance, good mechanical properties,

susceptible to solvents |

| Nylon | Excellent mechanical properties, high toughness, poor moisture

resistance |

| POM | High stiffness, excellent thermal & electrical properties,

relatively brittle |

Post-processing and surface finishes for CNC machining

CNC-machined parts as they emerge from the machine often exhibit

visible tool marks, a feature

that may not align with your specific part requirements.

Fortunately, there exists a multitude of post-processing techniques

aimed at enhancing the surface

appearance and elevating attributes such as wear resistance,

corrosion resistance, and chemical

resistance.

Methods like anodizing, bead blasting, and powder coating present

viable options for refining the

final presentation of your custom parts, allowing you to achieve the

desired surface quality and

performance characteristics.

| Surface Finishing Options for CNC Machining |

| Name | Applicable Materials | Can be Applied with |

| Alodine | Aluminum | Media Blasting, Tumbling, Type II Anodizing* Type III Anodizing*,

Type III Anodizing with PTFE* |

| Anodizing | Aluminum | Media Blasting, Tumbling, Alodine* |

| Black Oxide | Steel, Stainless Steel | Media Blasting, Tumbling, Passivation |

| Electroless Nickel Plating | Aluminum, Steel, Stainless Steel | Media Blasting, Tumbling |

| Electropolishing | Steel, Stainless Steel | — |

| Hand Polishing | Acrylic | Enhanced cosmetic appearance |

| Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | All post processes except Electropolish and Powdercoat |

| Nickel Plating | Aluminum, Steel, Stainless Steel | Media Blasting, Tumbling |

| Passivation | Steel, Stainless Steel | Black Oxide, Electroless Nickel Plating, Zinc Plating, Tumbling,

Media Blasting |

| Powder Coating | Aluminum, Steel, Stainless Steel | — |

| Tumbling | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | All post processes except Electropolish and Powdercoat |

| Vapor Polishing | CNC Polycarbonate (Clear, Black) | Enhanced cosmetic appearance, near optically clear applications |

| Zinc Plating | Steel, Stainless Steel | Media Blasting, Tumbling, Passivation |

Applications of CNC Machining

Turning, a precision manufacturing technique, is adept at producing

rotational, axi-symmetric

parts featuring intricate details such as holes, grooves, threads,

tapers, and contoured surfaces.

Its proficiency shines in crafting limited-quantity items,

particularly custom-designed shafts and

fasteners utilized in prototypes. Furthermore, turning serves as a

valuable complementary process,

enabling the addition or refinement of features to parts

manufactured through alternative methods.

Notable examples of products shaped through turning include

camshafts, crankshafts, baseball bats,

bowls, cue sticks, signboards, musical instruments, and the legs of

tables and chairs.

Company Profile

FAQ's

1. Why choose CNC machining?

The choice of CNC machining is characterized by its speed,

precision, and versatility.

This manufacturing solution distinguishes itself by efficiently

producing end-use parts across

various volumes, all without the necessity for significant

investments in hard tooling or

elaborate set-ups.

2. How long does delivery time and quotation take?

The delivery time for parts is intricately tied to their

complexity. Low-complexity parts usually

have a lead time of 2-3 days, while moderate complexity extends to

2-5 days.

High-complexity parts may necessitate a lead time ranging between 5

and 15 days.

Quoting time is also linked to design complexity, ranging from 1

business day or faster for

simpler designs to 3+ business days for more intricate ones.

If you have a design that requires assessment and quoting, do not

hesitate to contact our team.

3. What are the advantages of CNC machining?

CNC machining offers a spectrum of advantages, prominently

featuring rapid prototyping and

the expedited production of full-scale parts. Its hallmark is the

ability to achieve exceptional

precision and accuracy in manufacturing, catering to tight

tolerances for CNC parts of diverse sizes.

This method stands out for its flexibility, influencing factors

such as volume, pricing, lead times,

and the array of materials and finishes available.

4. Factors Influencing CNC Machining Costs:

The cost of CNC machining a part is influenced by several key

factors, including:

1. Material: Variations in material costs arise as some materials,

such as aluminum, are more

cost-effective to machine than others like Inconel due to increased

tool wear and slower cutting speeds.

2. Complexity: Parts with intricate features incur higher machining

costs. Complex surface shapes,

for instance, are notably more expensive to machine compared to

flat surfaces.

3. Tolerances: Stringent dimensional tolerances escalate machining

costs. Specifying unnecessarily

tight tolerances on non-critical features can contribute to

increased CNC machining expenses.

4. Surface Finish: Achieving mirror finishes necessitates

specialized tooling and machining strategies,

extending machining time and subsequently increasing costs.

5. Quantity: Low-volume production inherently comes at a higher

cost per part than large-volume

production. This is because initial setup and programming costs are

distributed over a greater number

of parts in large-volume production.