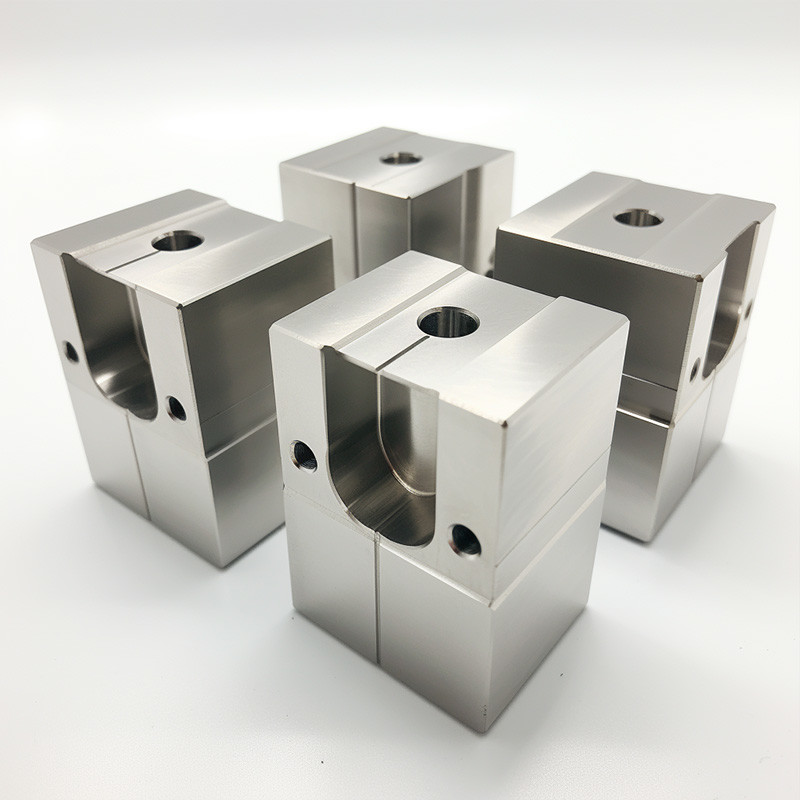

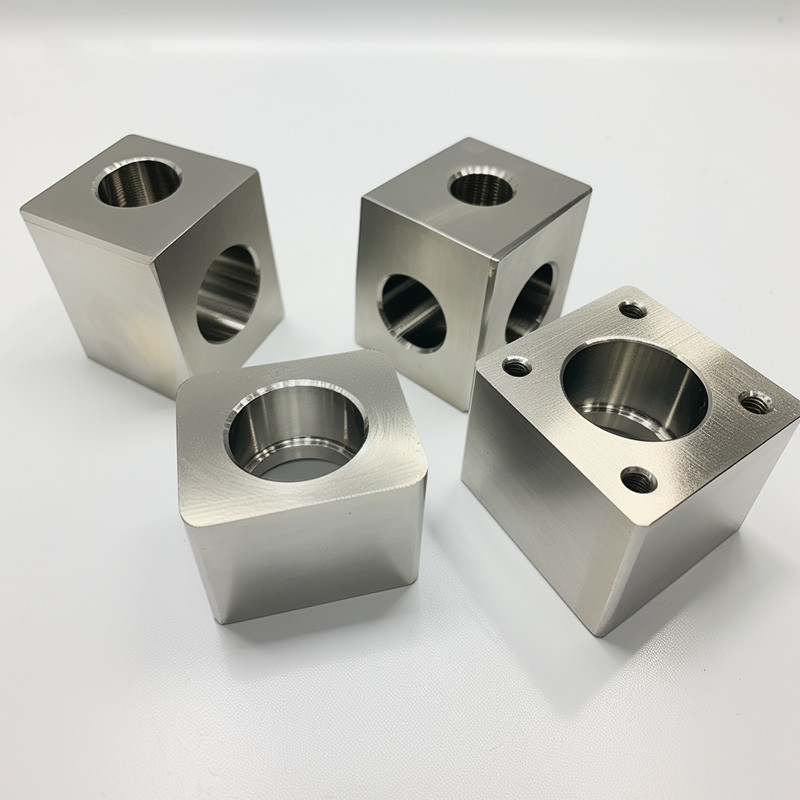

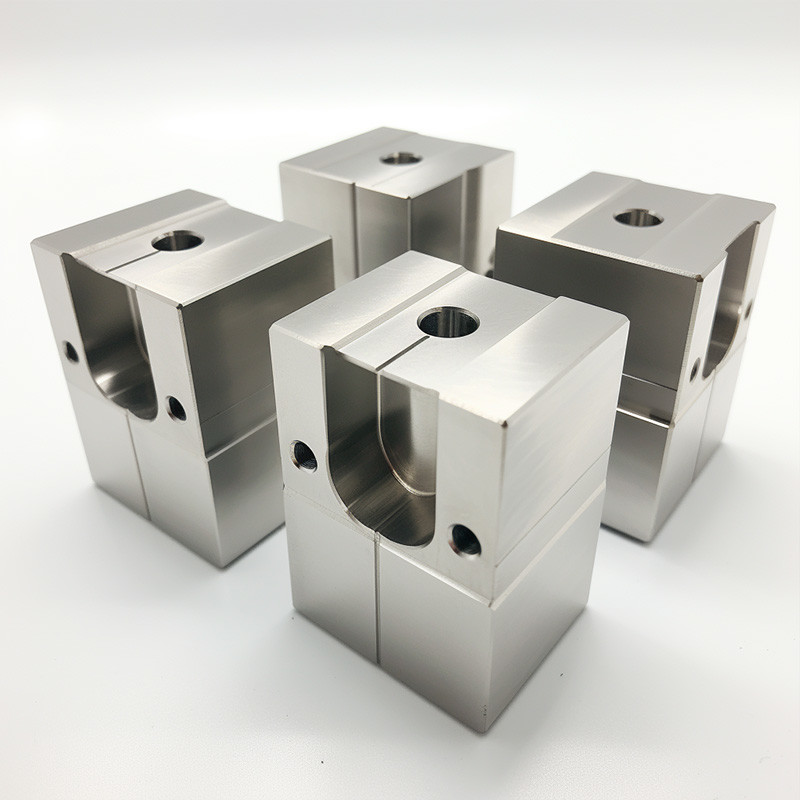

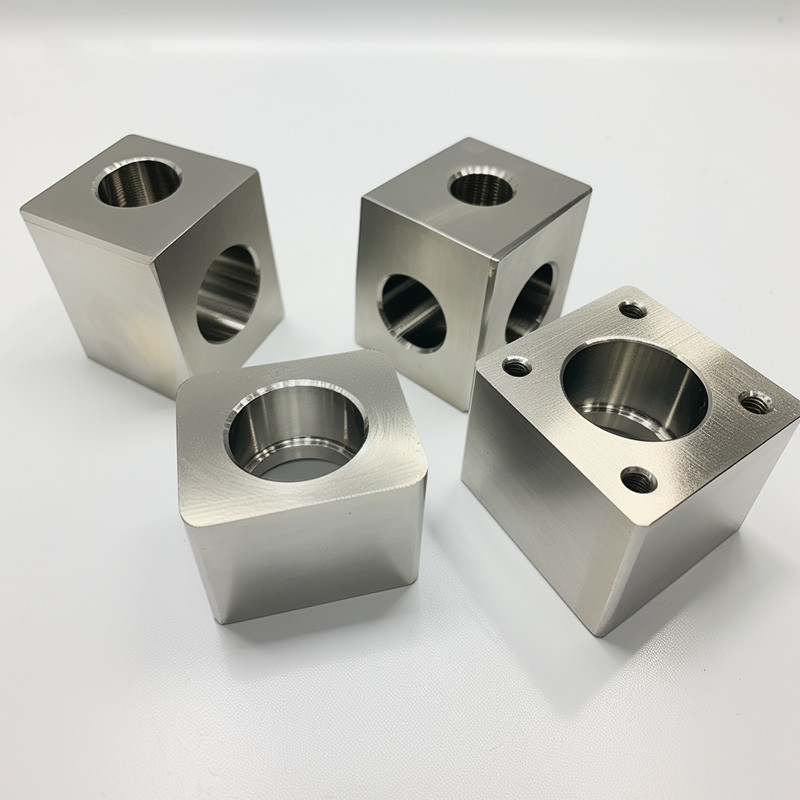

Custom CNC Machining Complex Parts CNC Machined Products Steel

Milled Metal Parts

CNC machining, short for computer numerical control machining, is a

subtractive manufacturing

technique that utilizes computerized controls and machinery to

selectively remove material layers

from a solid block. Precise cuts in the material are orchestrated

through programmed instructions,

allowing automated machinery to execute the machining tasks with

accuracy and efficiency.

Product Details

The CNC machining process predominantly employs metals as its

primary materials.

These metals encompass alloy steel, carbon steel, cast iron,

stainless steel, aluminum, copper,

magnesium, and zinc.

Nonetheless, this versatile process can also be applied to machine

plastic components and work

with an array of other materials, including ceramics, composites,

thermoplastics, and thermosets.

| Common Materials |

| Name | Description |

| Aluminum | High machinability and ductility, good strength-to-weight ratio. |

| Stainless steel | High tensile strength, corrosion and temperature resistant. |

| Mild steel | High machinability and weldability, high stiffness. |

| Brass | Low friction, excellent electrical conductivity, golden appearance. |

| Copper | Excellent thermal and electrical conductivity. |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive

and medical industries. |

| ABS | Common thermoplastic, impact resistant, easy to machine. |

| Nylon | Excellent mechanical properties, thermal, chemical and abrasion

resistant. |

| POM | High stiffness, high accuracy, low friction, easy to machine. |

Post-processing and surface finishes for CNC machining

CNC-machined parts as they emerge from the machine often exhibit

visible tool marks,

a feature that may not align with your specific part requirements.

Fortunately, there exists a multitude of post-processing techniques

aimed at enhancing the

surface appearance and elevating attributes such as wear

resistance, corrosion resistance,

and chemical resistance.

Methods like anodizing, bead blasting, and powder coating present

viable options for refining

the final presentation of your custom parts, allowing you to

achieve the desired surface

quality and performance characteristics.

| Surface Finishes |

| Name | Applicable to | Machining marks |

| As machined | Metals, Plastics | Visible, light surface scratches |

| Smooth machining |

| Fine machining | Metals | Slightly visible |

| Polishing | Metals | Removed on primary surfaces |

| Bead blasting | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Metals |

| Anodizing Type II | Aluminum |

| Anodizing Type III | Aluminum | Visible under anodizing |

| Black oxide | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible |

| Powder coating | Metals | Removed |

| Brushed + electropolishing | Stainless steel | Removed on Primary surfaces |

Specialist Industries

We’ve manufactured millions of parts for all sorts of applications,

but we’re especially

knowledgeable in these areas.

1. Aerospace & aviation

2. Automotive

3. Industrial machinery

4. Consumer electronics

5. Robotics & automation

6. Medical

Company Profile

Factors Influencing Machining Costs

The cost of CNC machining projects is influenced by various factors

that play a significant role

in cost estimation. Manufacturers seeking to manage expenses

effectively and optimize their

processes should be aware of these key elements that determine

machining costs:

1. Material Selection:

The choice of raw material directly impacts machining costs.

Different materials have varying costs, availability, and machining

characteristics.

High-performance alloys may be more expensive than common metals.

Material availability affects pricing, and considering material

type is essential for cost calculation.

2. Complexity of Design:

The complexity of the machined part affects cost determination.

Intricate features, tight tolerances, and complex geometries

require advanced machining

techniques, specialized tooling, and longer machining time.

Producing complex components requires additional precision and

expertise, increasing overall costs.

3. Machining Time:

Machining time is a critical cost factor.

Longer machining times result in higher costs.

Machining time includes cycle time, setup time, and overall

production efficiency.

Optimizing processes to reduce cycle time and enhance setup

efficiency minimizes costs and

improves productivity.

4. Machine Tooling:

The choice and management of machine tooling impact machining

costs.

Tooling costs, including purchase, maintenance, and replacement of

cutting tools, should be

considered.

Cutting tool lifespan and changeover time affect production

efficiency and costs.

Proper tooling selection, maintenance, and optimization control

expenses.

5. Volume and Batch Size:

Production volume and batch size directly affect machining costs.

Economies of scale apply to larger production volumes, reducing the

cost per part.

Balancing volume with setup time is crucial; small batches may have

higher costs due to

increased setup time, while larger volumes benefit from lower

per-part costs.

6. Labor Costs:

Labor costs, including wages for CNC machining engineers and

operators, contribute significantly

to expenses.

Skilled operators with expertise in CNC programming, setup, and

operation are essential.

Labor-intensive operations or complex part requirements may involve

additional labor costs.

7. Overhead Costs:

Overhead costs related to CNC machining operations impact overall

cost calculations.

These costs encompass facility expenses, utilities, administrative

costs, quality control, and

inspection.

Managing and optimizing overhead expenses are vital for cost

control and competitiveness.

8. Scrap and Rework:

Scrap and rework costs are crucial considerations.

Material waste due to errors or deviations from specifications

increases costs.

Effective quality control measures, precision machining techniques,

and robust inspection

processes minimize scrap and rework, reducing overall machining

expenses.

Understanding and analyzing these factors enables manufacturers to

identify areas for improvement,

implement cost-saving measures, and optimize CNC machining

processes for enhanced efficiency

and profitability.