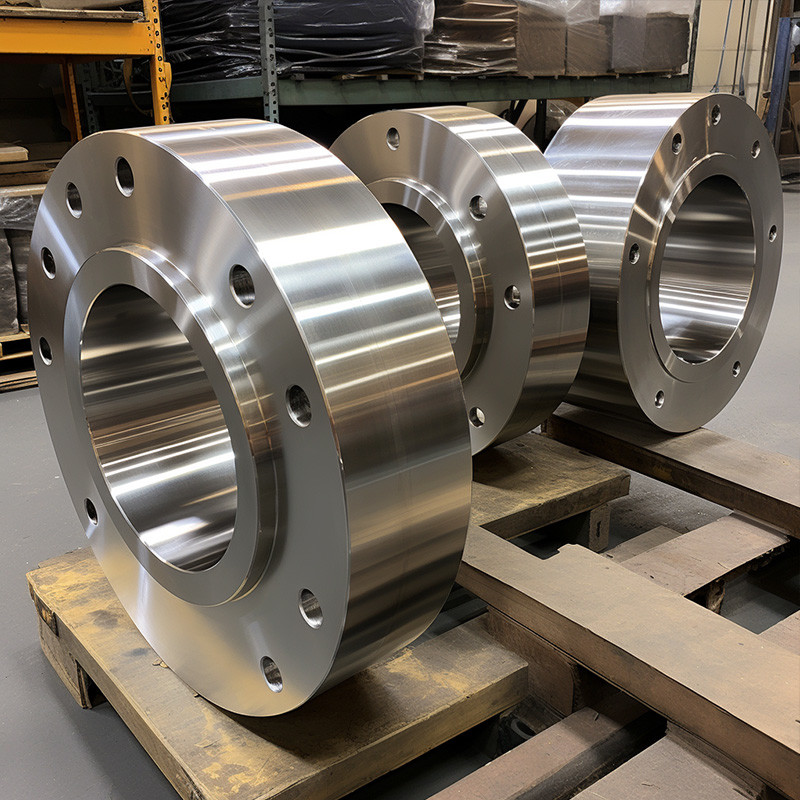

Stainless Steel Spare Part CNC Oem Parts CNC Machining Parts CNC

Precision

Turned Parts

CNC, short for computer numerical control, defines a machining

process driven by computer

commands. This technology enables faster, more accurate, and

intricate part production

compared to manual methods.

CNC machining reduces reliance on manual labor while enhancing

precision and complexity.

Although humans are vital for programming and machine operation,

the physical machining

tasks are automated. This synergy between human expertise and

computer-driven automation

ensures seamless and efficient operations.

Product Details

CNC machining can be used for a wide variety of materials, with the

most common being

aluminum, steel, brass, ABS, Delrin, and nylon. But really, almost

any hard material can be

CNC machined.

| Common Materials |

| Name | Description |

| Aluminum | High machinability and ductility, good strength-to-weight ratio. |

| Stainless steel | High tensile strength, corrosion and temperature resistant. |

| Mild steel | High machinability and weldability, high stiffness. |

| Brass | Low friction, excellent electrical conductivity, golden appearance. |

| Copper | Excellent thermal and electrical conductivity. |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive

and medical industries. |

| ABS | Common thermoplastic, impact resistant, easy to machine. |

| Nylon | Excellent mechanical properties, thermal, chemical and abrasion

resistant. |

| POM | High stiffness, high accuracy, low friction, easy to machine. |

Post-processing and surface finishes for CNC machining

CNC-machined parts as they emerge from the machine often exhibit

visible tool marks, a feature

that may not align with your specific part requirements.

Fortunately, there exists a multitude of post-processing techniques

aimed at enhancing the surface

appearance and elevating attributes such as wear resistance,

corrosion resistance, and chemical

resistance.

Methods like anodizing, bead blasting, and powder coating present

viable options for refining the

final presentation of your custom parts, allowing you to achieve the

desired surface quality and

performance characteristics.

| Surface Finishes |

| Name | Applicable to | Machining marks |

| As machined | Metals, Plastics | Visible, light surface scratches |

| Smooth machining |

| Fine machining | Metals | Slightly visible |

| Polishing | Metals | Removed on primary surfaces |

| Bead blasting | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Metals |

| Anodizing Type II | Aluminum |

| Anodizing Type III | Aluminum | Visible under anodizing |

| Black oxide | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible |

| Powder coating | Metals | Removed |

| Brushed + electropolishing | Stainless steel | Removed on Primary surfaces |

Specialist Industries

Parts produced by this type of machining are commonly found in the

automotive, aerospace,

medical, marine, and hydraulic industries. Such as headers,

housings, shafts, shells, knobs,

rotors, terminals, fittings, pistons, valve stems, and similar

products.

Company Profile

FAQ's

1. What are the benefits of CNC machining?

CNC machining offers several key advantages. It excels in rapid

prototyping and the speedy

production of full-scale production parts. With CNC machining, you

can achieve exceptional

precision and accuracy, making it ideal for tight tolerance

machining across a wide range of

part sizes.

Additionally, CNC machining provides maximum flexibility in terms

of volume, pricing, lead

times, as well as material and finish options.

2. What are typical machining tolerances?

Typical machining tolerances fall within the range of ± 0.005

inches or 0.13 millimeters.

Tolerances represent the allowable variation for a specific

dimension. For instance, if a CNC

machining tool has a tolerance of ± 0.01 millimeters, it means that

the tool can deviate by 0.01

millimeters in each cut.

When provided with a drawing, Our CNC machining service can achieve

CNC parts with

tolerances as tight as ± 0.0002 inches. In the absence of a

drawing, all CNC parts are

manufactured according to our ISO 2768 medium standard.

We can also work to even tighter tolerances, such as ± 0.025

millimeters or ± 0.001 inches,

when an engineering drawing specifies critical features.

3. What are the default fillet sizes in the absence of specified

dimensions from the

3D model or drawing?

When specific fillet dimensions are not provided, we will apply

fillet radii that facilitate machining,

as determined by our machinists' judgment. If you require a

particular fillet radius, please ensure

it is specified.

In the absence of specific details, typical internal vertical edge

radii may exceed 1/3 of the depth,

while internal horizontal edges can be either left sharp or have a

radius ranging from 0.5mm to

1mm, depending on the machining requirements.

4. Quality Assurance

At our company, we prioritize customer trust and adhere to

established quality management

principles. Our commitment to enhancing customer satisfaction

drives us to consistently improve

our performance and capabilities.

With decades of experience, we have a strong track record of

meeting stringent regulations and

maintaining compliance with PPAP standards for the automotive,

aerospace, and medical device

industries. These industries set high benchmarks that guide our

manufacturing processes for all

our products.