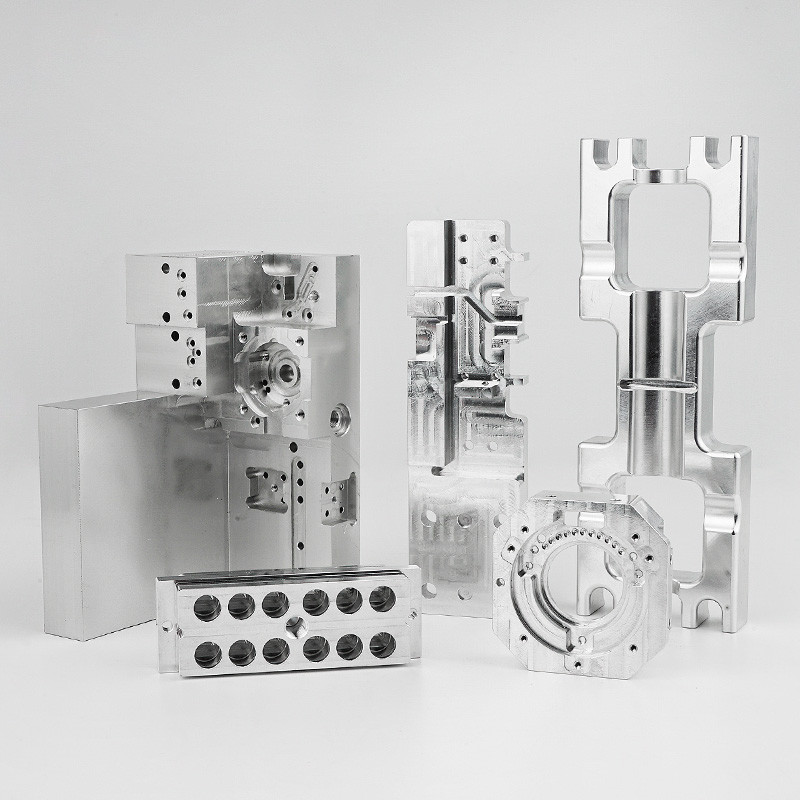

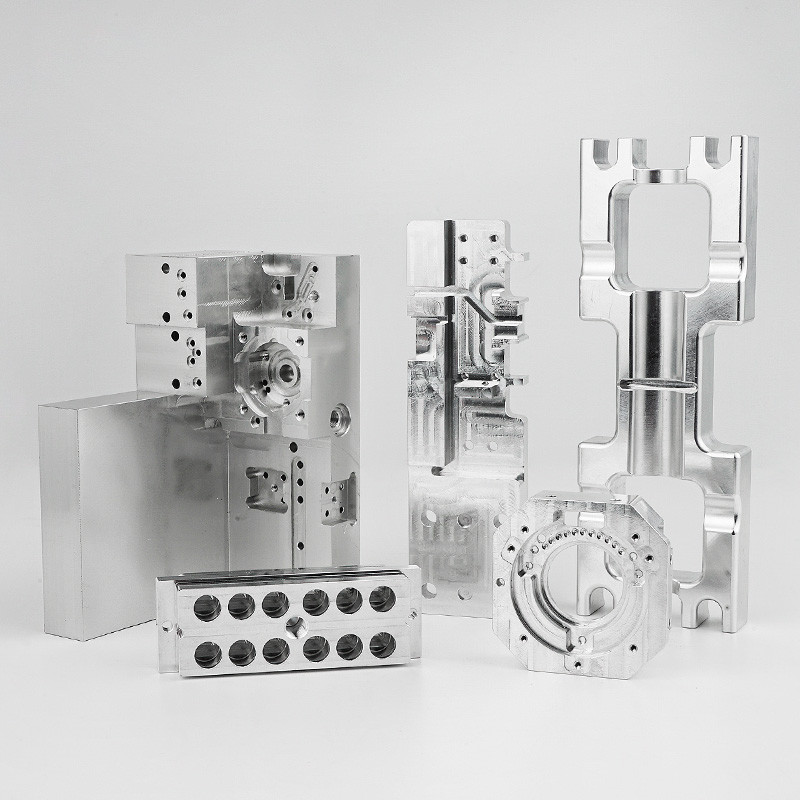

CNC Machining Services Custom Aluminum CNC Machining Part Milling

Machine Parts Aluminum

CNC Machining Services Custom Aluminum CNC Machining Part Milling

Machine

Parts Aluminum Stainless Steel

CNC, short for computer numerical control, defines machining

processes driven by computerized

systems. This technology enables faster, more accurate, and highly

precise part production,

accommodating intricate geometries that manual machining cannot

achieve.

CNC machining also minimizes the need for labor-intensive manual

work, although human

involvement remains crucial in programming and overseeing

operations for seamless results.

Product Details

CNC milling machines are capable of cutting a wide range of

materials, including aluminum,

bronze, copper, ceramics, plywood, various steel alloys, stone,

wood, zinc, and various

engineering materials.

This versatility makes them an excellent choice for crafting

prototypes during product development.

Furthermore, CNC milling allows for precise and rapid adjustments

until the desired final product is

achieved.

| The Most Popular Materials |

| Material | Characteristics |

| Aluminum 6061 | Good strength-to-weight ratio, excellent machinability, low

hardness |

| Stainless Steel 304 | Excellent mechanical properties, resistant to corrosion & acid, relatively difficult to machine |

| Brass C360 | High ductility, excellent machinability, good corrosion resistance |

| Copper | Excellent thermal and electrical conductivity |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive

and medical industries. |

| ABS | Excellent impact resistance, good mechanical properties, susceptible to solvents |

Nylon (PA6 & PA66) | Excellent mechanical properties, high toughness, poor moisture resistance |

| POM (Delrin) | High stiffness, excellent thermal & electrical properties,

relatively brittle |

Surface Finishing

We specialize in the production of custom-made products and offer

surface treatment services

tailored to meet our customers' specific requirements and industry

standards.

Our comprehensive solutions are both efficient and cost-effective,

making us a one-stop destination

with the capacity and capability to provide integrated services.

| Surface Finishing Options for CNC Machining |

| Name | Applicable Materials | Can be Applied with |

| Alodine | Aluminum | Media Blasting, Tumbling, Type II Anodizing* Type III Anodizing*,

Type III Anodizing with PTFE* |

| Anodizing | Aluminum | Media Blasting, Tumbling, Alodine* |

| Black Oxide | Steel, Stainless Steel | Media Blasting, Tumbling, Passivation |

| Electroless Nickel Plating | Aluminum, Steel, Stainless Steel | Media Blasting, Tumbling |

| Electropolishing | Steel, Stainless Steel | — |

| Hand Polishing | Acrylic | Enhanced cosmetic appearance |

| Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | All post processes except Electropolish and Powdercoat |

| Nickel Plating | Aluminum, Steel, Stainless Steel | Media Blasting, Tumbling |

| Passivation | Steel, Stainless Steel | Black Oxide, Electroless Nickel Plating, Zinc Plating, Tumbling,

Media Blasting |

| Powder Coating | Aluminum, Steel, Stainless Steel | — |

| Tumbling | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | All post processes except Electropolish and Powdercoat |

| Vapor Polishing | CNC Polycarbonate (Clear, Black) | Enhanced cosmetic appearance, near optically clear applications |

| Zinc Plating | Steel, Stainless Steel | Media Blasting, Tumbling, Passivation |

Application of CNC Machining Parts

The possibilities for CNC machining applications are virtually

limitless. Here are a few examples:

1. Woodworking: CNC machining is utilized in the production of

wooden furniture to save time

and reduce costs. It enables the creation of intricate furniture

designs that would be impractical

to craft manually.

2. Lettering and Engraving: CNC machines can perform precise

engraving tasks, whether for

artistic purposes or to mark serial numbers and patterns on

surfaces.

3. Electronics: CNC machining is essential in the electronics

industry for tasks like creating

mounting holes in printed circuit boards and machining heat sinks

for electrical components.

4. Pharmaceuticals: CNC machines manufacture precise equipment for

pharmaceutical production,

including metering pumps, dispensing nozzles, and packaging

machinery.

5. Food and Beverage: The fast-moving consumer goods industry

relies on custom material-handling

machinery with CNC-machined components. Additionally, CNC machining

is used to create molds for

injection-molded food packaging materials.

Company Profile

FAQ's

1. A Brief Overview of CNC Machining Parameters

In CNC machining, many parameters are determined by the machine

operator during the

generation of G-code.

Among these parameters, we will focus on the build size and

accuracy of CNC machines.

CNC machines are known for their relatively large build areas,

particularly when compared to

3D printers. CNC milling systems, for instance, are capable of

machining parts with dimensions of

up to 2,000 x 800 x 100 mm (78” x 32” x 40”), while CNC turning

systems can handle parts with

diameters of up to Ø 500 mm (Ø 20’’).

One of the notable advantages of CNC machining is its ability to

produce parts with exceptional

accuracy and tight tolerances. CNC machines can achieve tolerances

that are even less than half

the diameter of an average human hair, which is approximately ±

0.025 mm or .001’’.

In cases where the tolerance is not specified in the technical

drawing, the operator typically

machines the part with an accuracy level of 0.125 mm (.005’’).

2. CNC Machining Costs Demystified

The cost of CNC machining a part is influenced by various factors,

including:

1. Material: The choice of material affects cost, with materials

like Inconel being more expensive

due to increased tool wear and slower machining.

2. Complexity: Complex features drive up costs, as machining

intricate surface shapes is more

time-consuming.

3. Tolerances: Tight dimensional tolerances increase expenses;

specifying them unnecessarily on

non-critical features can inflate costs.

4. Surface Finish: Achieving mirror finishes demands specialized

tools and strategies, prolonging

machining time and costs.

5. Quantity: Low-volume production costs more per part due to

initial setup and programming

costs spread over fewer pieces.

3. Delivery Time and Quotation Turnaround

Our delivery time and quotation process are influenced by the

complexity of your project.

For low-complexity parts, expect a lead time of 2-3 days.

As complexity increases, the lead time can range from 2-5 days.

High-complexity parts may require

a lead time of 5-15 days.

Quotation turnaround time varies based on complexity as well. For

straightforward designs, we can

provide a quote within 1 business day or even faster.

However, for more intricate projects, the quoting process may take

3 or more business days.

If you have a design that needs assessment and a quote from our

team, please don't hesitate to

contact us.