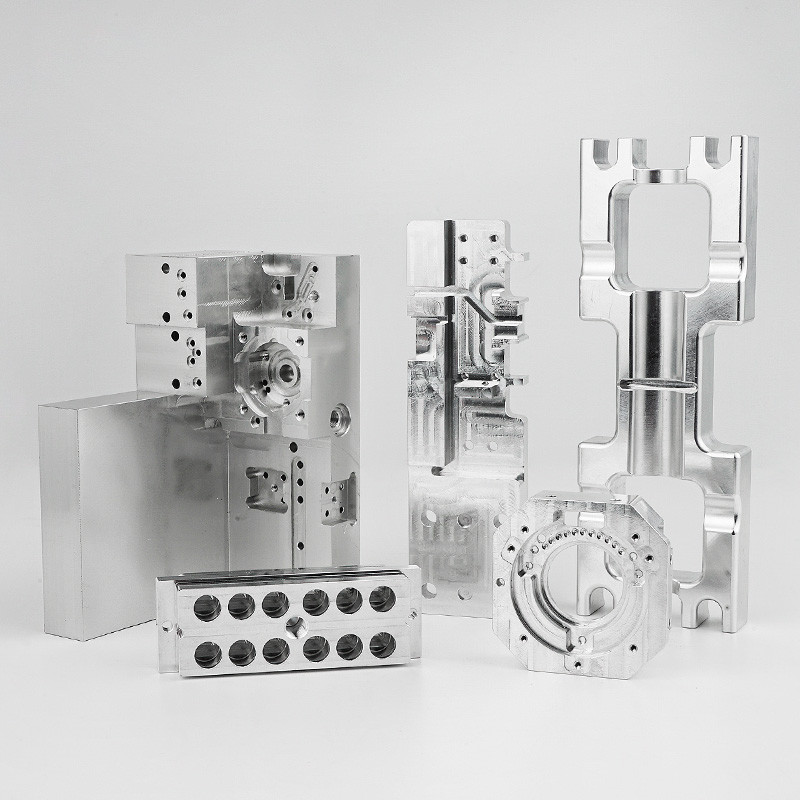

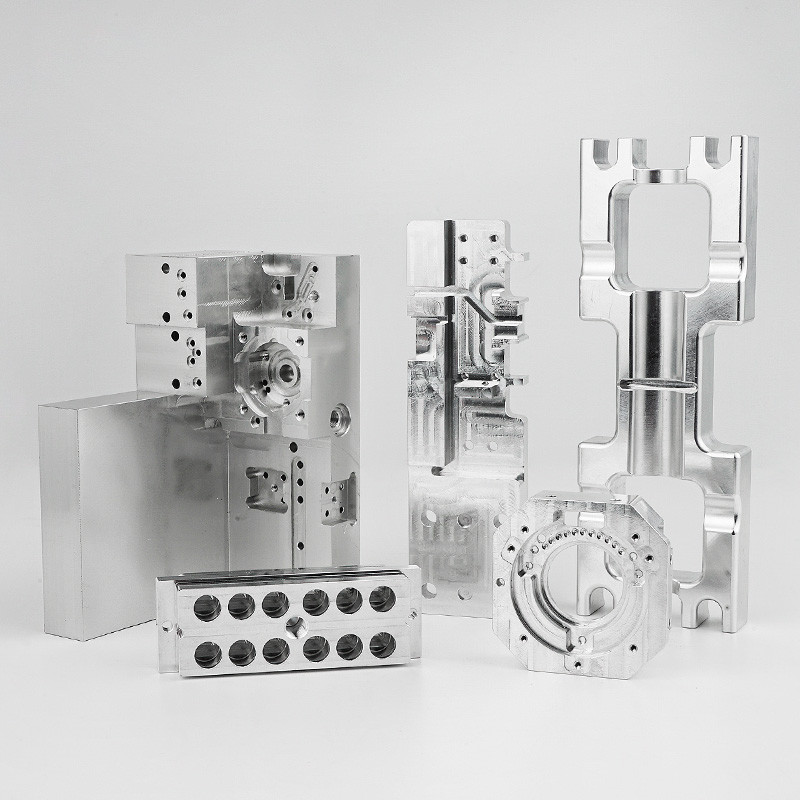

CNC Milling Machining Service Stainless Steel CNC Machining And

Part Small Aluminum CNC Parts

CNC Milling Machining Service Stainless Steel CNC Machining And

Part Small

Aluminum CNC Parts

Custom CNC machining is a widely embraced subtractive manufacturing

technique,

highly regarded for its ability to craft tailor-made metal and

plastic components, suitable for

both prototyping and production requirements.

By harnessing CAD (computer-aided design) modeling software in

tandem with G-code,

CNC milling and CNC turning machines efficiently remove material

from solid workpieces

with remarkable precision and efficiency.

CNC machines excel in producing robust parts characterized by

strict tolerances and a wide

array of exceptional material properties, encompassing both

mechanical and chemical attributes.

Our customized CNC machining service is ideally suited for

individual projects and medium-volume

production runs, leveraging automation and a high level of

reproducibility.

Product Details

We work with a diverse range of materials, including carbon alloys,

aluminum, brass,

stainless steel, high nickel alloys, and engineered plastics.

If you are uncertain about the best material for your specific

application, our expertise can

guide you in selecting the most suitable option, even if it happens

to be a material not

mentioned here.

Here is a comprehensive overview of the most popular materials

| The Most Popular Materials |

| Material | Characteristics |

| Aluminum 6061 | Good strength-to-weight ratio, excellent machinability, low

hardness |

| Stainless Steel 304 | Excellent mechanical properties, resistant to corrosion & acid, relatively difficult to machine |

| Brass C360 | High ductility, excellent machinability, good corrosion resistance |

| ABS | Excellent impact resistance, good mechanical properties, susceptible to solvents |

Nylon (PA6 & PA66) | Excellent mechanical properties, high toughness, poor moisture resistance |

| POM (Delrin) | High stiffness, excellent thermal & electrical properties,

relatively brittle |

Surface Finishing

We specialize in the production of custom-made products and offer

surface treatment services

tailored to meet our customers' specific requirements and industry

standards.

Our comprehensive solutions are both efficient and cost-effective,

making us a one-stop destination

with the capacity and capability to provide integrated services.

| Surface Finishes |

| Name | Applicable to | Machining marks |

| As machined | Metals, Plastics | Visible, light surface scratches |

| Smooth machining |

| Fine machining | Metals | Slightly visible |

| Polishing | Metals | Removed on primary surfaces |

| Bead blasting | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Metals |

| Anodizing Type II | Aluminum |

| Anodizing Type III | Aluminum | Visible under anodizing |

| Black oxide | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible |

| Powder coating | Metals | Removed |

| Brushed + electropolishing | Stainless steel | Removed on Primary surfaces |

Specialist Industries

CNC service a variety of industries, enabling the precise

manufacturing of components for

specific needs. Here are some key sectors and their respective

applications:

1. Transportation: CNC turning is integral to the aerospace,

automotive, mass transit, rail,

locomotive, military, and trucking industries.

It's used to create essential transportation equipment such as

headnuts, gear blanks, bearing

blocks, levers, axles, and rotors.

2. Construction: The construction sector relies on CNC machining to

produce robust components

capable of withstanding heavy loads.

Bolts, screws, and fasteners made from stainless steel and aluminum

are common CNC-machined

parts used for assembly and fastening purposes.

3. Vehicles: CNC turning services play a crucial role in

manufacturing various auto parts.

These include engine components like cylinder heads, connecting

rods, and camshafts, as well as

transmission parts such as shafts and rings.

Suspension elements like sway bars, control arms, and tie rod ends,

along with items like bushings

and bolts, are also produced using CNC turning.

4. Air Travel: The aviation industry heavily depends on CNC turned

parts for customizing and

fabricating probes, joint connectors, fasteners, as well as engine

and aircraft components.

Many aviation parts are crafted from titanium due to its

exceptional performance in extreme

temperature conditions.

Company Profile

7 Key Advantages of CNC Machining

1. Minimal to No Waste Generation: CNC machining excels in efficiency and material

conservation. Precision and accuracy reduce faulty cuts, resulting

in fewer discarded parts.

The ability to handle precise cuts and angles minimizes waste

production.

2. Exceptional Accuracy and Defect-Free Results: Precision is a significant benefit of CNC

machining. Computer-driven instructions and controlled movements

lead to consistent and closely

matching results.

This precision is invaluable for producing parts with tight

tolerances and virtually eliminates human

error.

3. Rapid and Efficient Production: CNC machining offers inherent speed and efficiency.

These machines produce items much faster and more efficiently than

traditional methods.

Many modern CNC units can operate autonomously, loading raw

materials and unloading finished

products without human intervention, increasing productivity and

cost-efficiency.

4. Faster Assembly: CNC-machined components lead to easier and quicker assembly.

The precision and consistency of CNC machining ensure that parts

fit together exactly as designed,

reducing the need for extensive fitting and adjustments.

5. Enhanced Safety: CNC machining removes significant safety risks from the shop floor

by

automating the process. It eliminates many hazards associated with

manual machining,

and CNC machines are often enclosed, further reducing injury risks.

6. Energy Efficiency: CNC machining consumes less electricity compared to older

processes,

leading to reduced energy consumption.

According to the EPA, CNC machining uses approximately one-seventh

of the energy of traditional

machining methods due to its speed and lower power draw.

7. Cost Reduction: CNC machining is a cost-effective, efficient, and precise

manufacturing process.

It also consumes fewer raw materials compared to conventional

methods. Embracing CNC technology

can significantly decrease errors, production costs, and overall

product expenses.