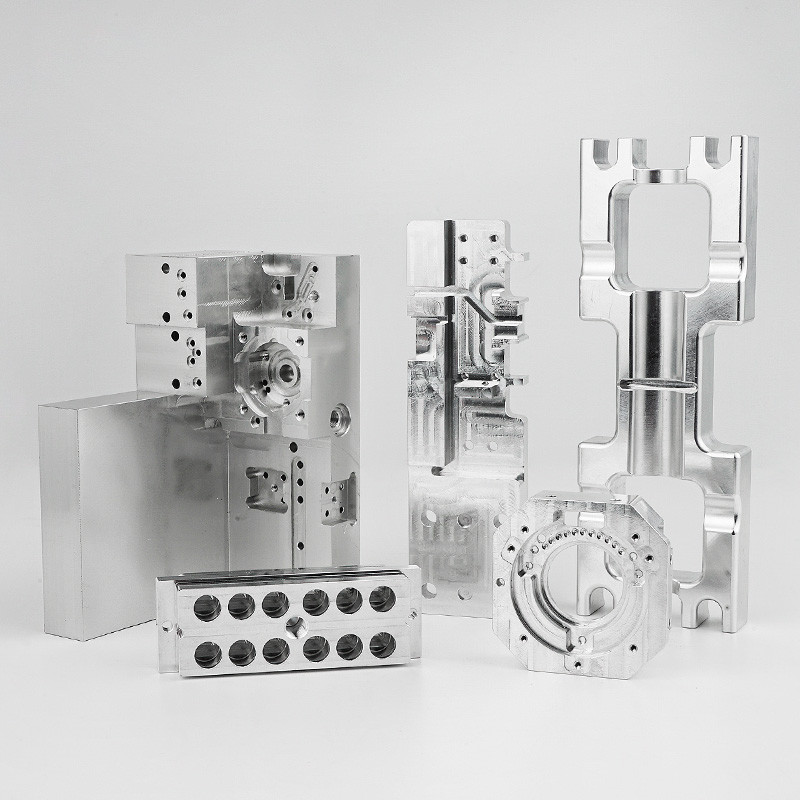

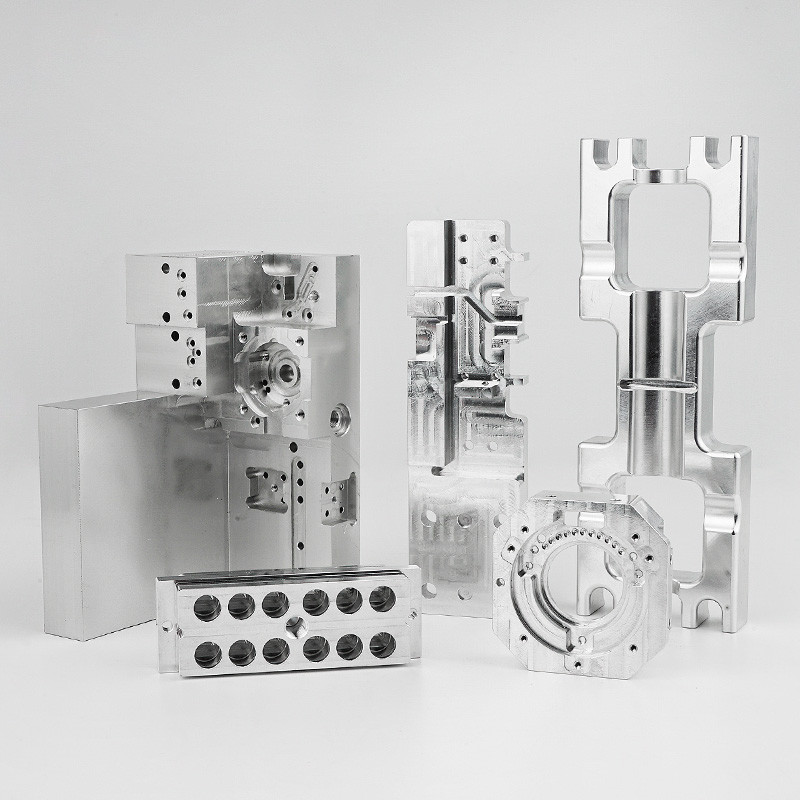

CNC Precision Machining Service Custom Aluminium Machined Part

Aluminum CNC Components

High Precision CNC Machining Center Milling Parts Machining Service

Aluminium

CNC Lathe Aluminum Machining Processing Parts

How does custom CNC machining service work?

Custom CNC machining is a widely adopted subtractive manufacturing

technology renowned

for its excellence in crafting bespoke metal and plastic components

tailored for both prototyping

and production needs.

By harnessing CAD (computer-aided design) modeling software in

conjunction with G-code,

CNC milling and CNC turning machines proficiently remove material

from solid workpieces with

exceptional precision and speed.

CNC machines are adept at producing durable parts characterized by

stringent tolerances

and a diverse range of outstanding material properties, both

mechanical and chemical in nature.

Our bespoke CNC machining service is ideally suited for singular

projects and medium-volume

production runs, capitalizing on automation and a high degree of

reproducibility.

Product Details

The cost of materials in CNC machining can fluctuate significantly

due to the extensive array of

available options.

Each material carries its unique price tag, and the inherent

physical properties of each material

play a substantial role in determining machining costs.

Here is a comprehensive overview of the most popular materials

| The Most Popular Materials |

| Material | Characteristics |

| Aluminum 6061 | Good strength-to-weight ratio, excellent machinability, low

hardness |

| Stainless Steel 304 | Excellent mechanical properties, resistant to corrosion & acid, relatively difficult to machine |

| Brass C360 | High ductility, excellent machinability, good corrosion resistance |

| ABS | Excellent impact resistance, good mechanical properties, susceptible to solvents |

Nylon (PA6 & PA66) | Excellent mechanical properties, high toughness, poor moisture resistance |

| POM (Delrin) | High stiffness, excellent thermal & electrical properties,

relatively brittle |

| Surface Finishes |

| Name | Applicable to | Machining marks |

| As machined | Metals, Plastics | Visible, light surface scratches |

| Smooth machining |

| Fine machining | Metals | Slightly visible |

| Polishing | Metals | Removed on primary surfaces |

| Bead blasting | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Metals |

| Anodizing Type II | Aluminum |

| Anodizing Type III | Aluminum | Visible under anodizing |

| Black oxide | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible |

| Powder coating | Metals | Removed |

| Brushed + electropolishing | Stainless steel | Removed on Primary surfaces |

Specialist Industries

We’ve manufactured millions of parts for all sorts of applications,

but we’re especially knowledgeable in these areas.

1. Aerospace & aviation

2. Automotive

3. Industrial machinery

4. Consumer electronics

5. Robotics & automation

6. Medical

Company Profile

FAQ's

1. How does CNC machining work?

CNC machining is a subtractive manufacturing process, meaning it

achieves its final product by

removing material.

It involves tasks like drilling holes, creating slots and pathways,

and shaping metal stock into

different forms with varying dimensions and designs.

Unlike additive manufacturing, which builds up materials layer by

layer, CNC machining subtracts

material to create shapes.

It also differs from injection molding, where material is injected

into a mold to form a specific shape.

CNC machining is highly versatile and compatible with a wide range

of materials, including metals,

plastics, wood, glass, foam, and composites.

This versatility has made CNC machining a popular choice in various industries, offering efficient

and precise fabrication for designers and engineers.

2. What are your tolerances for machined parts?

Our tolerances for machined parts are typically within

+0.005"/-0.005" for most metal geometries,

and within +/- 0.010" for plastics. However, tolerances may vary

for larger parts, especially when

maintaining flatness over extensive sections post-heat treatment.

Regarding the finish requirements, an "As Milled" finish should

have a minimum of 125 surface finish

for CNC parts.

For all fabricated parts, there is a dimensional tolerance of

0.010" and an angular tolerance of 1°.

Please note that tapped holes not explicitly indicated as features

in the provided CAD model may be

machined to the specified diameters in that model.

Additionally, surface treatments like anodizing, bead blasting,

iriditing, powder coating, etc., will only

be applied if they have been paid for and explicitly acknowledged

in advance.

3. Do you offer Quick-Turn CNC Machining?

Certainly! We provide rapid turnaround times for CNC machining,

with the option for many parts to be

completed in just 3-4 days.

We also offer an expedited service, and our dedicated team

collaborates closely with you to ensure your

most urgent deadlines are met.