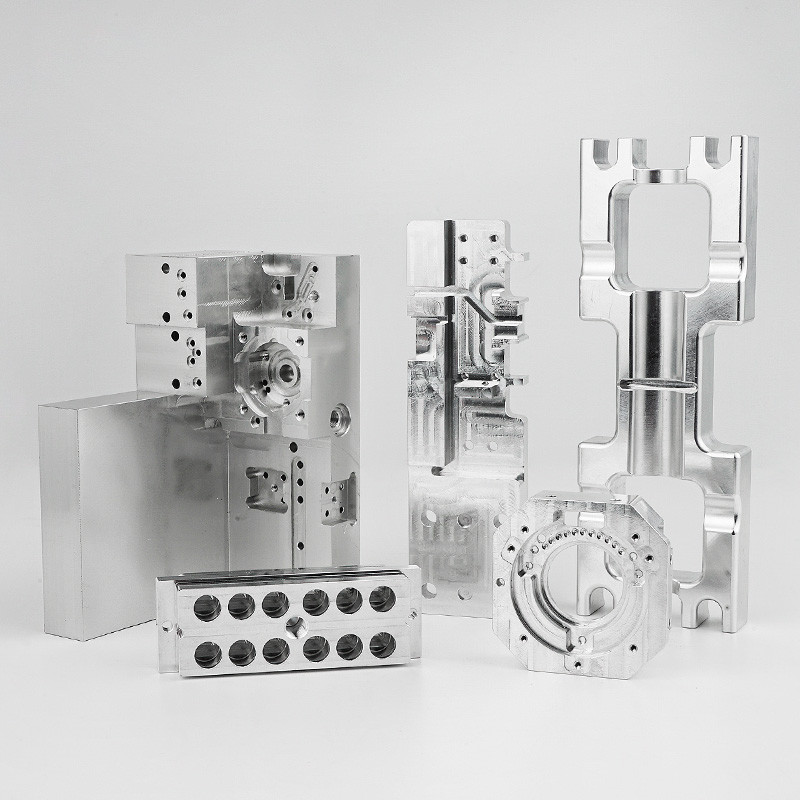

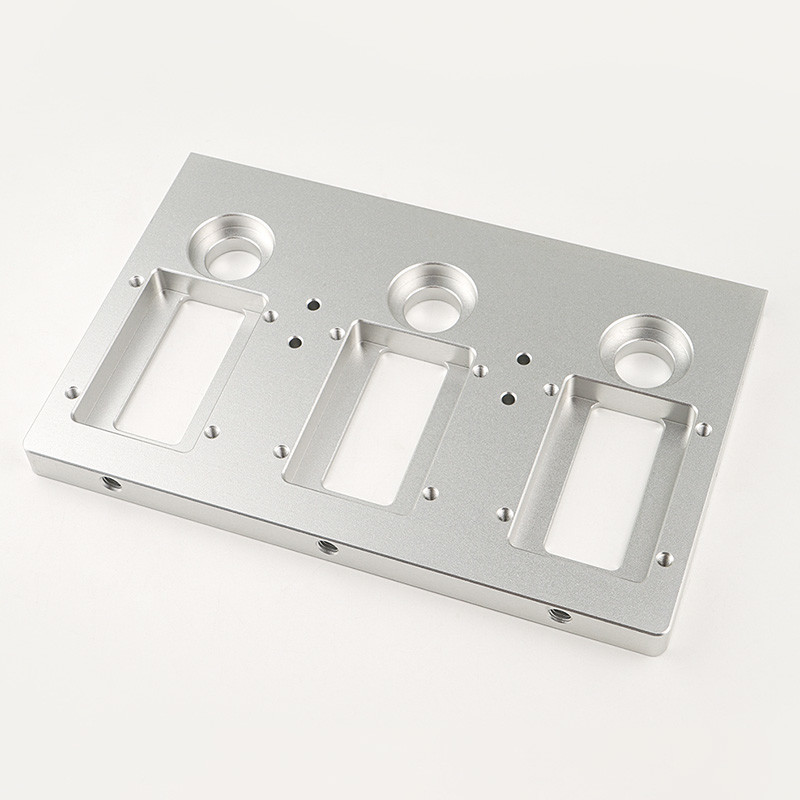

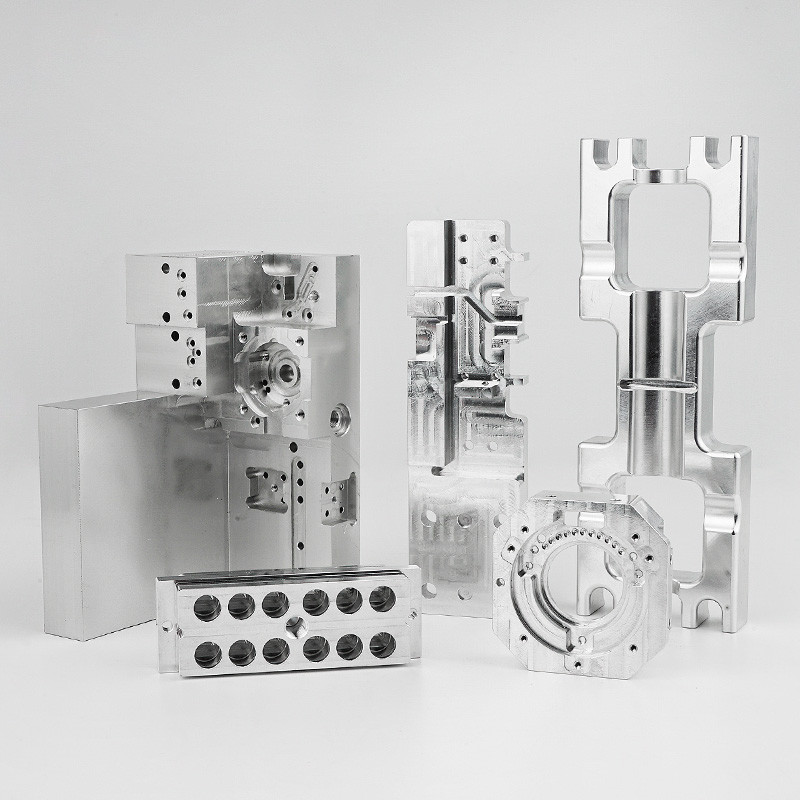

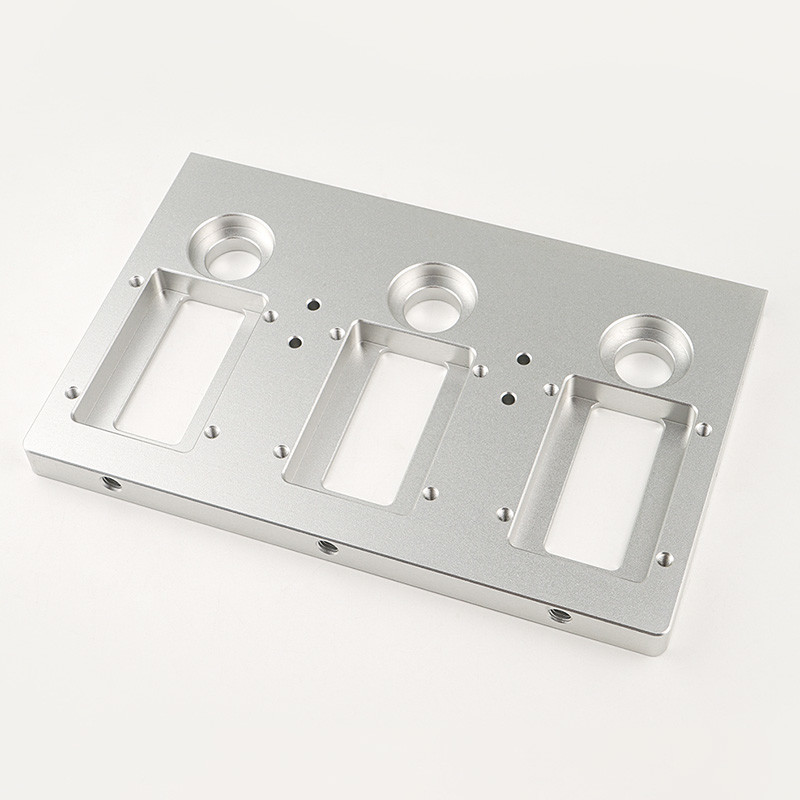

Custom CNC Milling Machining Services Stainless Steel CNC Machining

Milling Parts

Our CNC mills, or CNC milling machines, are capable of producing

parts in almost any shape,

using a variety of materials.

From soft metals like aluminum to tougher metals like steel, and even plastics such as acetal,

we provide cost-effective milling services.

Whether you require a single part, a batch of prototypes, or a full

production order,

we have you covered.

Product Details

We have experience working with a wide range of materials,

including carbon alloys, aluminum,

brass, stainless steel, high-nickel alloys, and engineered

plastics.

If you're unsure about the best material for your specific

application or if you're considering a

material that isn't listed here, our team can provide guidance and

assistance.

| Common Materials for CNC Machining |

| Material | Properties |

| Aluminum | 2024: Good fatigue resistance and strength; excellent toughness at

moderate to high strength levels; improved fracture toughness |

| 6061: Excellent machinability, low cost, and versatility |

| 7075: High strength, hardness, low weight, and heat tolerance |

| Brass | Versatile and highly attractive copper/zinc alloy with warm yellow

color accommodates severe forming/drawing |

| Copper | High ductility and high electrical and thermal conductivity;

develops attractive blue-green surface patina over time |

| Stainless Steel | Excellent machinability and outstanding uniformity; good

workability and weldability, high ductility and formability |

| Steel Alloy | Mix of chromium, molybdenum, and manganese yields toughness, good

torsional and fatigue strength |

| Steel Mild Low Carbon | High machinability and weldability, high stiffness; good mechanical

properties, machinability, and weldability at low cost |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive,

and medical industries |

| ABS | Excellent impact resistance, good mechanical properties,

susceptible to solvents |

| Nylon | Excellent mechanical properties, high toughness, poor moisture

resistance |

| POM | High stiffness, excellent thermal & electrical properties,

relatively brittle |

| CNC Milling Tolerances |

| Limits for nominal size | Plastics | Metals |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.10mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.20mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.30mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.50mm |

| Over 2000mm to 4000mm | ±2.0mm | |

*Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing. |

CNC Machining Applications

CNC milling is employed to fabricate products composed of glass,

metal, plastic, wood, and

custom-designed components.

Machinists utilize this process to create prototypes and items for

various industries, including

aerospace, automotive, hardware startups, manufacturing, medical

devices, robotics, and others.

Company Profile

FAQ's

1. What tolerances can be achieved?

Tolerances are not standardized across all processes and materials.

The final tolerances on your part depend on various factors, such

as part size, design complexity,

the number and size of features, materials used, surface finish,

and the manufacturing process

employed.

Once your order is confirmed, we conduct a Design for Manufacturing

review to identify areas

that may need modification for better manufacturability.

It's helpful if you can specify which areas in your design have

critical tolerances that must be

met and which can be adjusted, if necessary, to optimize production

time and cost.

Here are some general tolerance guidelines:

General tolerances for CNC machining in metal and plastic.

Tolerances for plastic injection molding.

Reference charts for CNC machining of metals and plastic injection

molding materials.

General tolerance for metal 3D printing is +/- 0.5mm.

A shrinkage rate of +/- 0.15% can be expected for vacuum casting.

All manufacturing and technical specifications must be clearly

defined in the 2D drawings to

be followed accurately.

2. How does you ensure part quality?

Upon order confirmation, we conduct a comprehensive Design for

Manufacturing (DFM) review

to identify and address any potential issues that could impact part

quality.

We meticulously inspect and verify incoming materials using

advanced testing equipment.

We provide final inspection reports prior to shipment.

Our real-time inspection data sharing capabilities allow us to

collaborate with you in addressing

any quality concerns that may arise during production.

3. Advantages of CNC Machining

1. Fast and Repeatable

Quick removal of large amounts of metal material, parts ready as

fast as 1 day

2. Accuracy

High-precision tolerances ranging from +/-0.005″ – 0.01″, depending

on customer specs.

3. Wide Range of Materials

Choose from over 50 metal and plastic materials.

4. Scalable Volume

CNC Machining has scalable volumes for production of 1-100,000

parts.

5. Custom Surface Finishes

Suitable for many different kinds of substrates, make your parts

just the same as real products.

6. Cost Saving

Low investment in tooling and preparation costs, economical for

parts with simple structure.